Iimveliso

Ukuchaneka okuphezulu kweTungsten Carbide epolishiweyo ngeentonga zeBar Round

Intshayelelo yeMveliso

Iirodi zeCarbide zisetyenziswa ikakhulu kwi-drill bits, i-end-milling cutters kunye nee-winches. Ingasetyenziselwa ukusika, ukunyathela kunye nezixhobo zokulinganisa. Isetyenziswa kwiphepha, ukupakishwa, ushicilelo, imboni non-ayoni processing metal. Ukongeza, isetyenziswa kakhulu ekwenzeni izisiki zentsimbi ezinesantya esiphezulu, izisiki zokugaya i-carbide, izixhobo zokusika i-carbide, izixhobo zokusika ze-NAS, izisiki zenqwelomoya, iibits ze-carbide, i-bits ye-milling cutter, i-high speed, i-taperd milling cutters, i-metric milling cutters, i-micro end milling cutters, i-hinge pilot, isixhobo sombane,ifayile ye-carbide rotary, isixhobo se-carbide esinesamente, njl.

Iinkcukacha zeMveliso

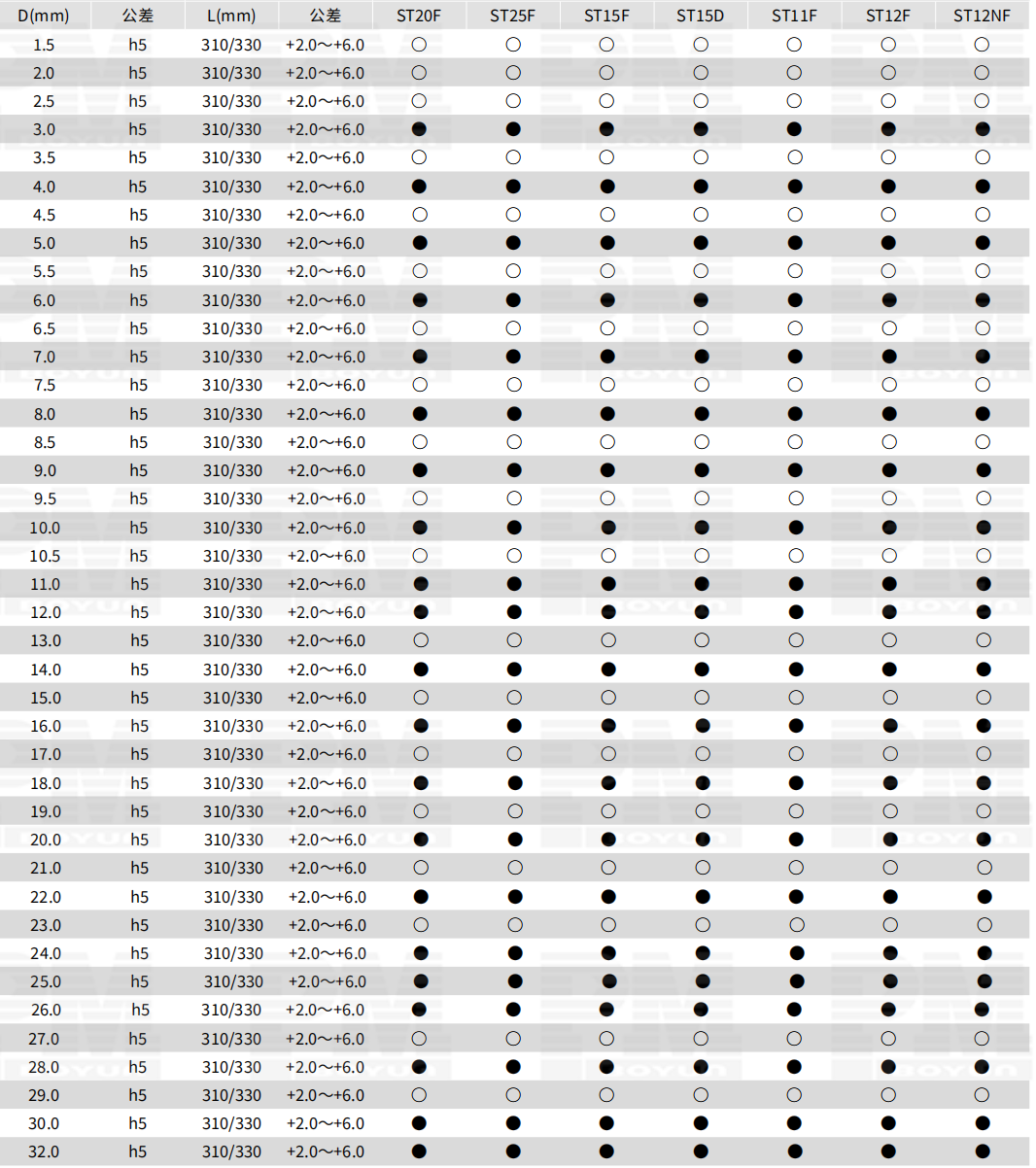

Ubungakanani obubhekiselweyo

Itshathi yeBanga leMathiriyeli

| Intshayelelo yeBanga kwiCarbide Rods | |||||||

| IBanga | Co % | Ubungakanani beenkozo zeWC | HRA | HV | Ubuninzi (g/cm³) | Amandla okugoba (MPa) | Ukuqina kokwaphuka (MNm-3/2) |

| I-KT10F | 6 | I-submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| I-KT10UF | 6 | kakuhle kakhulu | 93.8 | 2040 | 14.7 | 3200 | 9 |

| I-KT10NF | 6 | inanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| I-KT10C | 7 | Kulungile | 90.7 | 1480 | 14.7 | 3800 | 12 |

| I-KT11F | 8 | I-submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| I-KT11UF | 8 | kakuhle kakhulu | 93.5 | 1960 | 14.5 | 3000 | 9 |

| I-KT12F | 9 | kakuhle kakhulu | 93.5 | 1960 | 14.4 | 4500 | 10 |

| I-KT12NF | 9 | inanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| I-KT15D | 9 | I-submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| I-KT15F | 10 | I-submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| I-KT20F | 10 | I-submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| I-KT20D | 10 | I-submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| I-KT25F | 12 | kakuhle kakhulu | 92.4 | 1740 | 14.1 | 5100 | 10 |

| I-KT25EF | 12 | kakuhle kakhulu | 92.2 | 1700 | 14.1 | 4800 | 10 |

| I-KT25D | 12 | kakuhle kakhulu | 91.5 | 1570 | 14.2 | 4200 | 13 |

| I-KT37NF | 15 | inanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Bhala umyalezo wakho apha kwaye uwuthumele kuthi