Iimveliso

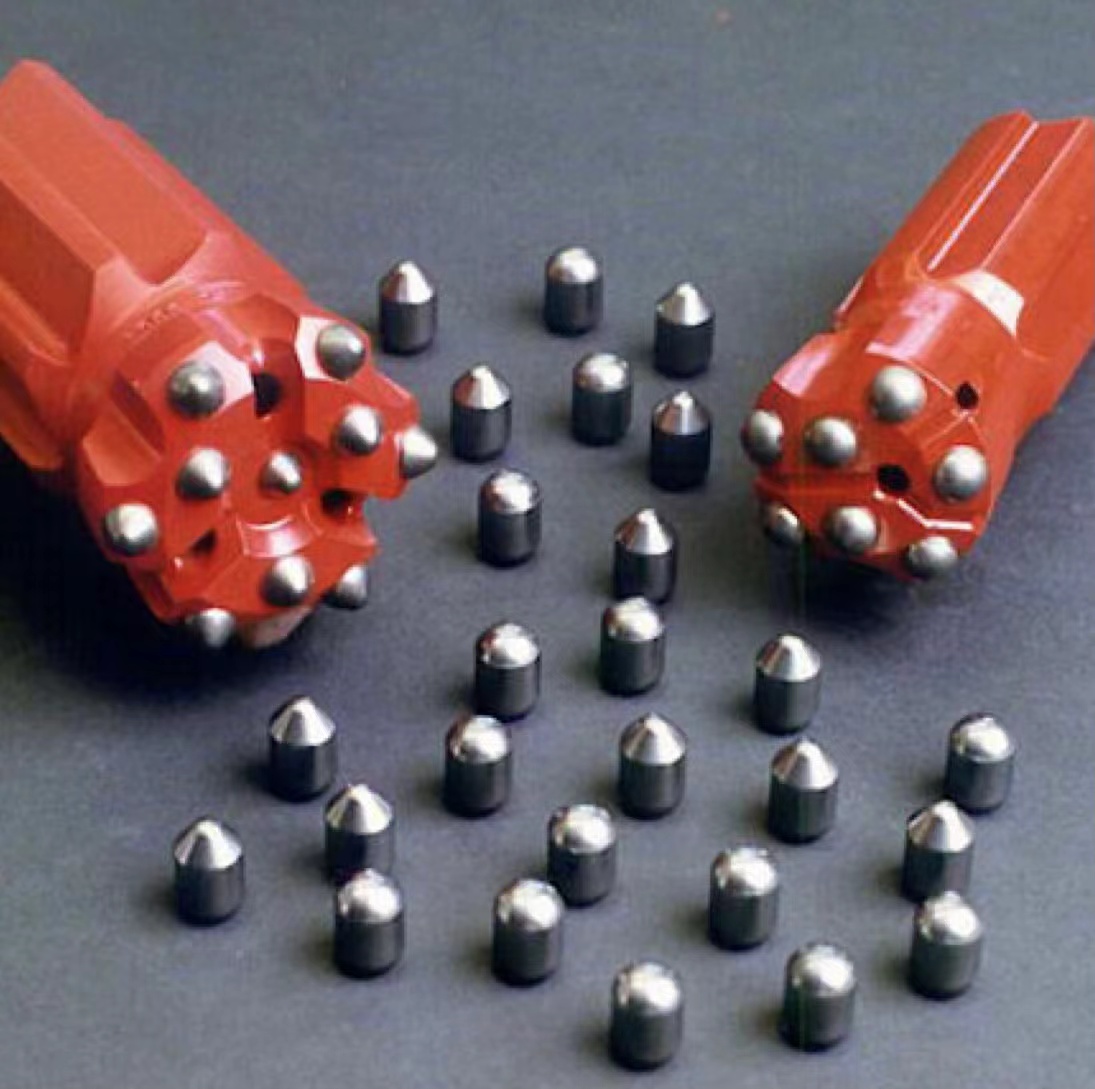

Amaqhosha eTungsten Carbide yeeBits zeRock

Izibonelelo

1. Yenziwe ngomgangatho ophezulu we-carbide wokuzinza kunye nomgangatho ohambelanayo.

2. Ukusetyenzwa ngeteknoloji yokuvelisa yamva nje ye-HIP sintered ukuvelisa umgangatho ophezulu.

3. Ukuhlolwa komgangatho ongqongqo kukhapha inkqubo yemveliso iyonke ukuqinisekisa ukuba yonke ibhetshi yemveliso iyahlangabezana nomgangatho wabathengi phambi kokuba ibekwe emarikeni.

4. Uluhlu olubanzi lwebanga le-tungsten carbide kunye nobukhulu bokukhethwa.

5. Ukuthunyelwa kwefektri-ngqo kuqinisekisa ixesha elifutshane lokuhambisa.

6. Sikwanikezela ngeengcebiso ezinamava ukukunceda uvelise eyona mveliso ingcono ngexabiso eliphantsi.

7. Amaqhosha e-carbide ngokwezifiso akhoyo, njl.

Inkqubo yeMveliso

Ukugaya--Ukwahlula-hlula njengoko kufuneka--Ukusila okumanzi--Omileyo--Granulation--Cofa--Sinter--Uhlolo--Package

Umzobo weenkcukacha

IBanga lokuReference

| IBanga | Ukuxinana | TRS | Ubunzima HRA | Usetyenziso |

| g/cm3 | MPa | |||

| YG4C | 15.1 | 1800 | 90 | Isetyenziswa ikakhulu njengempembelelo ye-drill yokusika izinto ezithambileyo, eziphakathi kunye nezinzima |

| YG6 | 14.95 | 1900 | 90.5 | Isetyenziswa njengebit yamalahle e-elektroniki, i-coal pick, i-petroleum cone bit kunye ne-scraper ball tooth bit. |

| YG8 | 14.8 | 2200 | 89.5 | Isetyenziswa njenge-core drill, ibit yombane yamalahle, i-coal pick, i-petroleum cone bit kunye ne-scraper ball tooth bit. |

| YG8C | 14.8 | 2400 | 88.5 | Isetyenziswa ikakhulu njengezinyo lebhola lentwana kunye nobungakanani obuphakathi obunempembelelo encinci kunye netyholo elithwele i-rotary exploration drill. |

| YG11C | 14.4 | 2700 | 86.5 | Uninzi lwazo lusetyenziswa kumasuntswana eempembelelo kunye namazinyo ebhola asetyenziselwa ukusika izinto ezinobulukhuni obuphezulu kumasuntswana ekhowuni. |

| YG13C | 14.2 | 2850 | 86.5 | Isetyenziselwa ikakhulu ukusika amazinyo ebhola ephakathi kunye nezixhobo ezinobunzima obuphezulu kwi-rotary impact drill. |

| YG15C | 14 | 3000 | 85.5 | Sisixhobo sokusika sokomba i-oyile kunye ne-oyile ethambileyo kunye nokugrumba amatye aqinileyo. |