Iimveliso

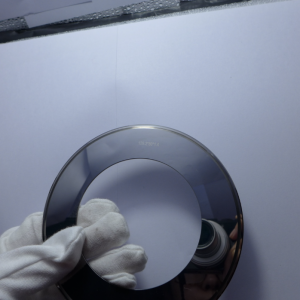

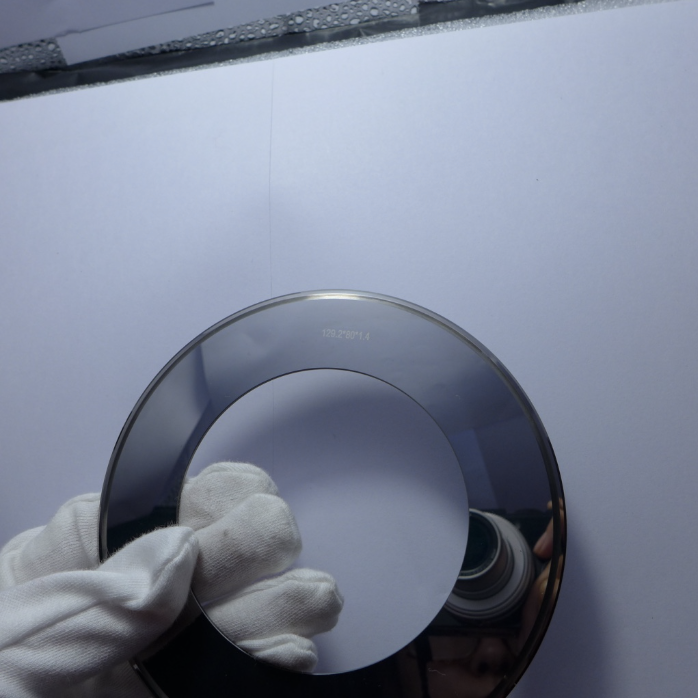

I-Tungsten carbide circular slitting blade yoshishino lwebhetri ye-lithium

Intshayelelo yeMveliso

Uluhlu olutsha lwamandla e-alloy i-lithium ibhetri ye-electrode eqhubekayo yokuqhawula imela yenziwe nge-cemented carbide powder ngokucinezela kunye ne-sintering, eneempawu zobunzima obuphezulu, ukuxhathisa okuqinileyo, i-anti sticking knife njalo njalo. Isebenza ngokukhethekileyo ekusombululeni zonke iintlobo zezinto ezimbi ezinje ngokuncamathela imela, uthuli, i-burr, imela eprintiweyo ngasemva, i-wavy edge, umahluko wombala njalo njalo. I-blade yokuhlola epheleleyo yandiswa ngamaxesha angama-500 ngaphandle kwenotshi. Ngethuba lenkqubo yokuqhawula iiplati ezintle kunye nezibi ze-lithium ibhetri ye-lithium, ukuchithwa komphetho kunye ne-burr okubangelwa umgangatho ombi we-slitting edge kuya kubangela ukuba ibhetri yengxaki yesiphaluka esifutshane kwaye yenze ingozi enkulu yokhuseleko. I-Chengdu Kedel Tools Co., Ltd. ineminyaka emininzi yamava ekuveliseni izixhobo zoshishino lwe-carbide enesamente. Zonke i-alloy blanks ziveliswa ngokwethu, kwaye inokuqonda okunzulu kokusila kunye nokulungiswa kwezixhobo ze-alloy. Ukubambelela kumoya "wengcibi", lawula ngokungqongqo ukunyamezela kwe-blade. Itekhnoloji ekhethekileyo yokusika itekhnoloji yokucoca ngokuchanekileyo kunye ne-100% yokusika izixhobo ezizenzekelayo inkqubo yokuhlola epheleleyo iqinisekisa ukusebenza okugqwesileyo kwe-lithium ibhetri ye-pole slice slitter.

Iimpawu zeMveliso

1. I-Hard alloy tungsten impahla yentsimbi, enokumelana okunamandla;

2. Umgca wokusika unokuchaneka okuphezulu kwe-machining, kwaye ukuchaneka kobunzima bunokufikelela kwi-microns ezi-3;

3. Ubomi benkonzo ende, utshintsho oluncinci lwesixhobo, ukusebenza kweendleko eziphezulu, ukusika ubude ukuya kwi-20000 yeemitha;

4. Isangqa sangaphandle se-blade sinokuhambelana kakuhle, i-blade edge ikhuliswe ngokungqongqo, kwaye akukho ngqungquthela ngexesha lokufumanisa, kwaye i-burr incinci;

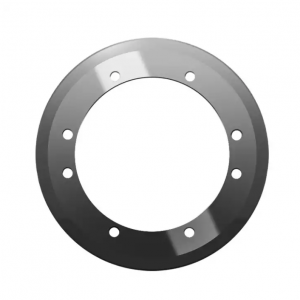

5. Ngokukodwa isetyenziselwa ukusika isinyithi esingenawo isinyithi njenge-lithium ibhetri yesiqhekeza, i-ceramic diaphragm, i-copper foil, i-aluminium foil, njl;

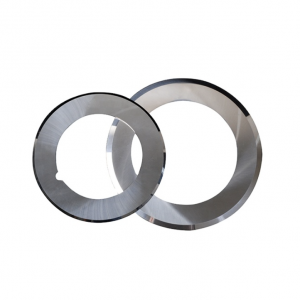

6.Iincakuba zohlulwe zibe ngamaqela aphezulu emela kunye neqela lemela elisezantsi, ezisetyenziswa kwiiseti ezipheleleyo.

Izinto eziphathekayo

| IBanga | Ubungakanani benkozo | Ubuninzi (g/cm³) | HRA | Ukuqina kokuqina (kgf/mm²) | TRS (MPa) |

| KS26D | isohlwayo esiphantsi | 14.0-14.1 | 90.4-90.8 | 19-20 | 4000-4800 |

Iimpawu eziphambili kunye nemilinganiselo

| Ubungakanani obuqhelekileyo | ||||

| HAYI. | Igama lemveliso | Imilinganiselo(mm) | Iengile yomda | Izinto zokusika ezisebenzayo |

| 1 | Ukusika imela ephezulu | Φ100xΦ65x0.7 | 26°, 30°,35°,45° | Isiqwenga sepali yebhetri yeLithium |

| Ukusika imela esezantsi | Φ100xΦ65x2 | 26°, 30°,35°,45°90° | ||

| 2 | Ukusika imela ephezulu | Φ100xΦ65x1 | 30 ° | Isiqwenga sepali yebhetri yeLithium |

| Ukusika imela esezantsi | Φ100xΦ65x3 | 90° | ||

| 3 | Ukusika imela ephezulu | Φ110xΦ90x1 | 26°, 30° | Isiqwenga sepali yebhetri yeLithium |

| Ukusika imela esezantsi | Φ110xΦ75x3 | 90° | ||

| 4 | Ukusika imela ephezulu | Φ110xΦ90x1 | 26°, 30° | Isiqwenga sepali yebhetri yeLithium |

| Ukusika imela esezantsi | Φ110xΦ90x3 | 90° | ||

| 5 | Ukusika imela ephezulu | Φ130xΦ88x1 | 26°, 30°,45°90° | Isiqwenga sepali yebhetri yeLithium |

| Ukusika imela esezantsi | Φ130xΦ70x3/5 | 90° | ||

| 6 | Ukusika imela ephezulu | Φ130xΦ97x0.8/1 | 26°, 30°,35°45° | Isiqwenga sepali yebhetri yeLithium |

| Ukusika imela esezantsi | Φ130xΦ95x4/5 | 26°, 30°,35°,45°90° | ||

| 7 | Ukusika imela ephezulu | Φ68xΦ46x0.75 | 30°, 45°, 60° | Isiqwenga sepali yebhetri yeLithium |

| Ukusika imela esezantsi | Φ68xΦ40x5 | 90° | ||

| 8 | Ukusika imela ephezulu | Φ98xΦ66x0.7/0.8 | 30°, 45°, 60° | I-Ceramic diaphragm |

| Ukusika imela esezantsi | Φ80xΦ55x5/10 | 3°, 5° | ||

| QAPHELA: Ukwenziwa ngokwezifiso kufumaneka ngomzobo wabathengi okanye isampuli yokwenyani | ||||

Iinkcukacha zeMveliso

Imeko yesicelo