Iimveliso

1/4” (6mm) I-Shank Tungsten carbide rotary burrs

Inkcazo yeMveliso

Ifayile ye-cemented carbide rotary, eyaziwa ngokuba yi-cemented carbide high-speed assorted milling cutter, i-cemented carbide die milling cutter, njl. Ifayile ejikelezayo ye-carbide isetyenziswe ngokubanzi koomatshini, iimoto, iinqanawa, imboni yeekhemikhali, ukukrola ubugcisa kunye namanye amacandelo oshishino. Ifayile ejikelezayo ye-hard alloy ingasetyenziselwa ukucubungula isinyithi, isinyithi, i-carbon steel, i-alloy steel, i-stainless steel, i-hardened steel, i-copper kunye ne-aluminium, njl.

Izibonelelo

1. Iyakwazi ukucubungula isinyithi esityhidiweyo, insimbi yentsimbi, i-carbon steel, i-alloy steel, insimbi engenasici, ithusi, i-aluminiyam kunye nezinye isinyithi, kunye ne-marble, i-jade, ithambo kunye nezinye i-nonmetals. Ubunzima bokucubungula bunokufikelela kwi-HRA ≥ 85.

2. Inokuthi indawo yevili elincinane lokusila ngomqheba, kwaye akukho lungcoliseko lothuli.

3. Ukusebenza kakuhle kwemveliso. Ukusetyenzwa kakuhle kuphindwe kaninzi kunelo lefayile yesandla kwaye phantse amaxesha alishumi aphezulu kunolo lwevili elincinane lokugaya elinesiphatho.

4. Umgangatho wokuqhuba kakuhle kunye nokugqiba okuphezulu. Iyakwazi ukwenza imingxunya eyahlukeneyo yokungunda echanekileyo.

5. Ubomi benkonzo ende. Ukuqina kumaxesha angama-10 aphezulu kunomsiki wentsimbi enesantya esiphezulu kunye namaxesha angama-200 aphezulu kunolo lwevili elincinci lokusila.

6. Kulula ukuyiqonda, kulula ukuyisebenzisa, ikhuselekile kwaye inokuthenjwa.

7. Iindleko ezibanzi zokulungisa zinokucuthwa amaxesha amaninzi.

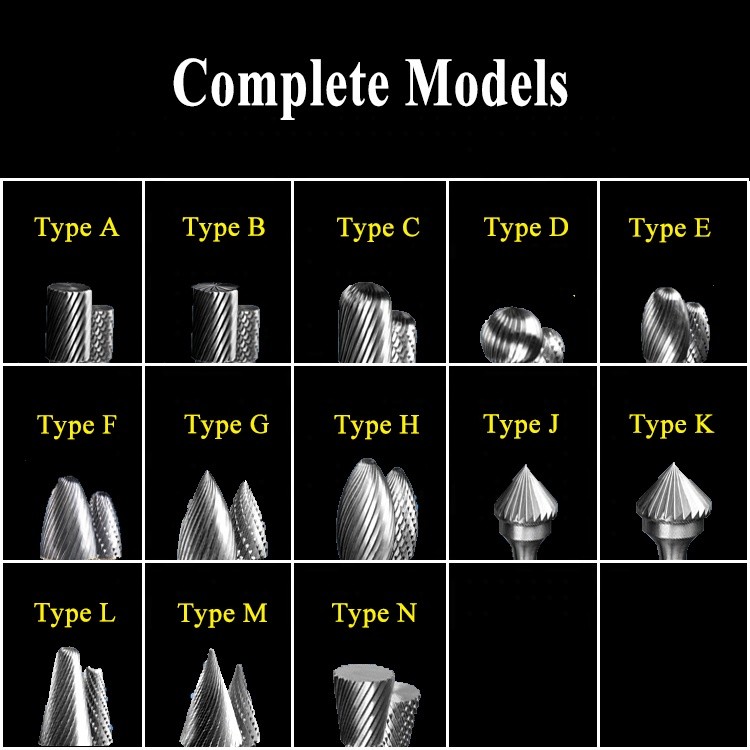

Iintlobo eziphambili

Ubume A Cylindrical Plan End

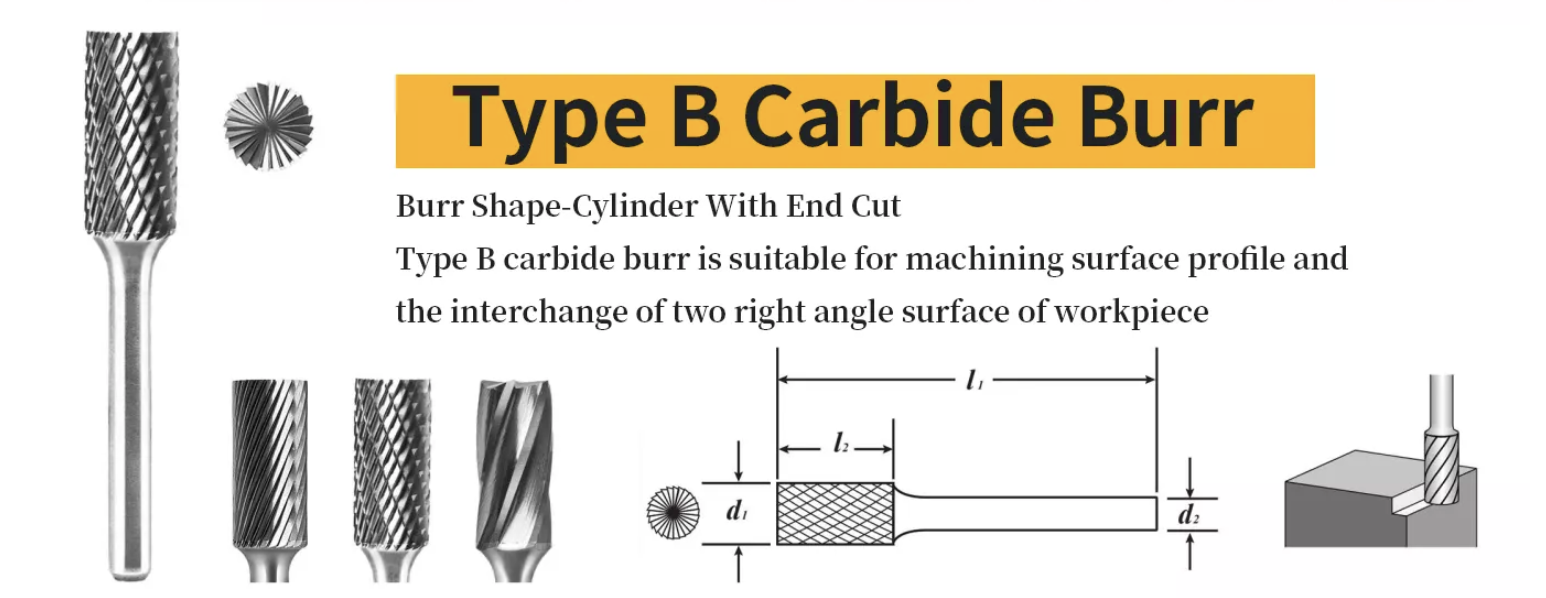

Ubume B Cylindrical End Cut

Imilo C Cylindrical Ball Nose

Imilo yeBhola ye-D

Imilo E Oval Shape

Imilo F Umthi Radius End

Imilo yeMilo ye-G yoMthi

Shape H Flame Shape

Ubume J 60-degree countersink

Ubume i-K 90-degree countersink

Imilo L Cone Radius End

Imilo yekowuni enguM eJombe imilo

Imilo N Ikhowuni eguqulweyo

Iisayizi eziphambili

| Ubungakanani beMetric | ||||||

| IShank Diameter(mm) | Umsiki weDayimitha (d1) | Ubude bokuSika(l2) | IShank Diameter(d2) | Ubude buBonke(L1) | Inombolo yesixhobo. | Uhlobo |

| 6.0 | 6 | 16 | 6 | 50 | B60616 | eqinileyo |

| 6 | 16 | 6 | 61 | B60616 | brazed | |

| 8 | 20 | 6 | 65 | B60820 | brazed | |

| 10 | 20 | 6 | 65 | B61020 | brazed | |

| 11 | 20 | 6 | 70 | B61125 | brazed | |

| 12 | 25 | 6 | 70 | B61225 | brazed | |

| 16 | 25 | 6 | 70 | B61625 | brazed | |

| 20 | 25 | 6 | 70 | B62025 | brazed | |

| 25 | 25 | 6 | 70 | B62525 | brazed | |