Iimveliso

I-6mm yeShank Diameter Sika kabini ukumila komthi ngeRadius End shape Tungsten Rotary Carbide Burr

Izibonelelo zeKedel carbide burrs

1,Yenziwe ngobushushu bonyango lwe-Solid tungsten carbide YG8 ehlala amaxesha angama-8 obomi bokusebenza Ukuqina kunesixhobo se-HSS

2, i-Kedel cabide yokusika iibhula zezixhobo zokusila- ilungela uninzi lwezigri ze-Rotary Die

3,Ihlala ixesha elide: Yenziwe ngetungsten carbide ephethwe bubushushu ukuze ubulukhuni bufikelele kwi-HRC70, ibukhali kwaye yomelele.

I-4, i-Versatile: Isetyenziselwa ngokubanzi isinyithi, ukwenza izixhobo, imodeli yobunjineli, ukukrola umthi, ukwenza ubucwebe, ukuwelda, ukukhwela, ukuphosa, ukuchithwa, ukugaya, ukuthuthwa kwentloko yesilinda kunye nokukrola.

5,Ithagethi:Ifanelekile kuwo onke amanqanaba ezakhono: le yikhithi ebalulekileyo yabenzi bomthi kunye nabathandi abacoca iiwelds okanye basebenze ngentsimbi rhoqo, kulula ukuyiqonda nokusebenzisa, ikhuselekile kwaye ithembekile.

I-6, iKhuseleko: Ipakishwe ngecala leplastiki yokugcina ukhuseleko kunye nokukhusela

Ingcaciso yeMveliso

| Ukwenziwa | ixabiso Factory wholesale, OEM Service kuwe |

| Uphawu | KEDEL |

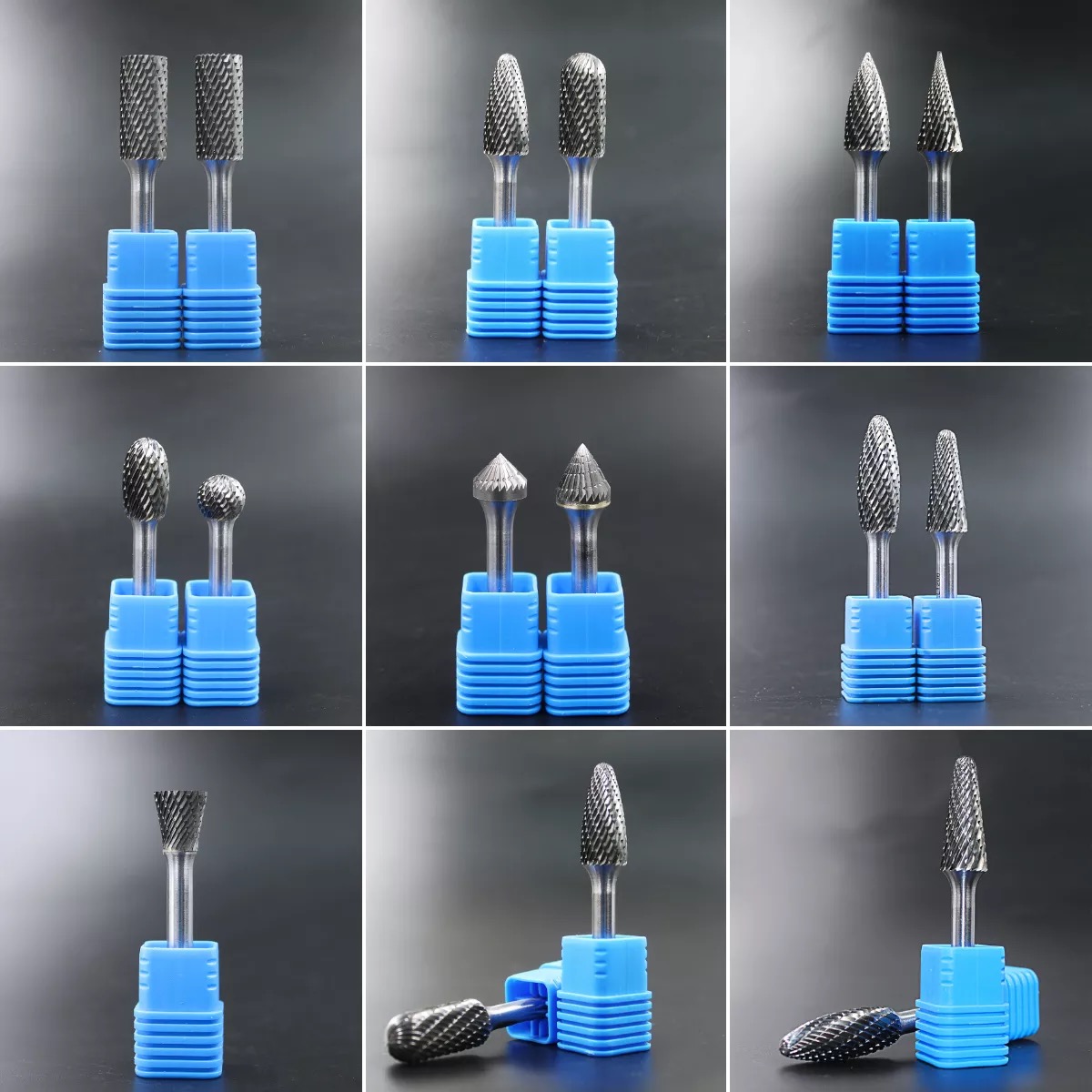

| Ubume boMsiki | A/B/C/D/E/F/G/H/J/K/L/M/N Uhlobo |

| Izinto eziphathekayo | 100% Tungsten steel Hard Carbide |

| Idayamitha yentloko | 3mm 4mm 6mm 8mm 10mm 12mm 14mm 16mm |

| Idayamitha yeShank | 1/2inch /1/4inch/1/8inch |

| HRA | HRA 89-92.5 ubulukhuni |

| Ifanelekile | Ukugrumba, Ukuthanda isinyithi, ukukrola, ukupolisha |

| Customized | OEM & ODM |

| I-KEDELTOOLS ivelisa uluhlu olubanzi lwee-carbide burs ezikumgangatho ophezulu kunye neesarha ze-bi-metal hole. I-KEDELTOOLS burs ihambisa ukusebenza okuphezulu kakhulu kokususa isitokhwe kubomi babo bonke benkonzo, ibonelela ngeziphumo ezibalaseleyo ngexesha elincinci. | |

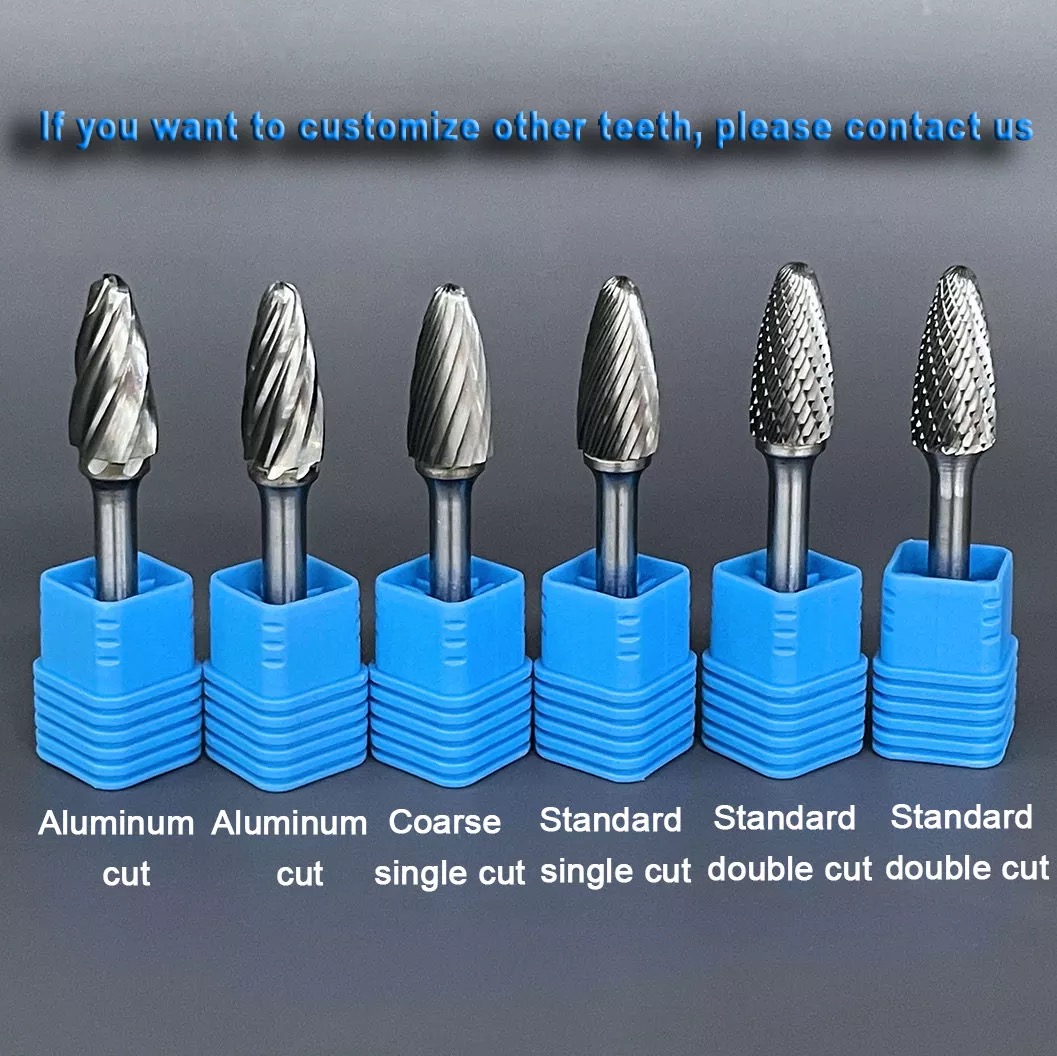

| I-Tungsten Carbide Conical Pointed Nose Rotary Burrs Use for Isinyithi sesinyithi Isinyithi esilukhuni i-aluminiyam ialloys yoBronze Ezinye iintsimbi ezingezizo i-ferrous Intsimbi eqinileyo Intsimbi engenakutyiwa (INOX) Icase-hardened iintsimbi Intsimbi, intsimbi etyhidiweyo Eqinileyo, iintsimbi eziphathwe ngobushushu ngaphezu kwe-1,200 N/mm2 (ngaphezu kwama-38 HRC) Iintsimbi eziqinisiweyo, eziphathwa bubushushu ngaphezu kwe-1,200 N/mm2 (ngaphezu kwama-38 HRC) Iintsimbi eziqinileyo, eziphathwa bubushushu ngaphezu kwe-700 N/mm² (> 220 HB) EGrey/enodular cast iron (GG/GJL, GGG/GJS) Ubhedu Intsimbi ethambileyo engeyiyo intsimbi Intsimbi eqinileyo engeyiyo intsimbi emnyama (GTS, GJMB) Intsimbi eqhotsiweyo efakwe intsimbi. Iintsimbi ukuya kuthi ga kwi-1,200 N/mm² (< 38 HRC) Iintsimbi ukuya kwi-700 N/mm² (< 220 HB) Intsimbi etyhidiweyo imathiriyeli yentsimbi enobunzima obungaphezulu kwe-54 HRC Intsimbi eqholiweyo yeTitanium Titanium alloys White annealed cast iron cast (GTW, GJMW) Isixhobo sentsimbi iZinc | Ipateni yokusika: * DX: Sika kabini * C: I-Coarse Cut * M: ISiko Elilodwa Eliqhelekileyo * W: Aluminiyam Sika Single Sika * F: Fine Single Single * Z: Phosa iSika enye * MX: I-Standard Cross Gear Cut * ZX: Ukuphosa uMnqamlezo * L: Idayimani Sika * I-SX: Ifayile yeSteel Cross Cut * FX: I-Fine Tooth Cross Cut *CX: I-Coarse Cross Cut * I-WX: I-Aluminiyam Cut Cross Cut * Okunye Qhagamshelana nathi |

| Iinkcukacha : * HRA: ≥ 85 * I-RPM ecetyisiweyo: 25000-50000, Max RPM 70000 * Iphakheji: Ipakishwe ngumntu ngamnye kwaye inokwenziwa ngokwezifiso * Itekhnoloji: I-100% I-Flat ephantsi yesilivere ye-welding tungsten carbide burrs | Iimbonakalo: * Isetyenziselwa ukucubungula zonke iintlobo zesinyithi (kubandakanywa nentsimbi eqinile) kunye ne-nonmetal * Ukusebenza okuphezulu kwemveliso, kunokunciphisa ubungakanani bomsebenzi obulungele ukusetyenziswa. * Isetyenziswa kakhulu kwizixhobo zomoya okanye zombane. |

Isicelo

Iyakwazi ukucutshungulwa ngentsimbi, intsimbi, intsimbi yekhabhoni, intsimbi yealloyi, intsimbi engatyiwa, ubhedu, ialuminiyam kunye nezinye iintsimbi, kunye nebhastile, ijade, ithambo kunye nezinye ezingezizo ezentsimbi. Ukucutshungulwa kobunzima ukuya kuthi ga kwi-HRA85.

Inzuzo

1. 10 iminyaka amava professional.

2. 100% imathiriyeli entsha.

3. Yomelela ngakumbi.

4. OEM & ODM Service.

5. Yonke imigaqo yentlawulo ixhaswa.

6. Ixesha lokuhambisa ngokukhawuleza kunye nokuThuthwa okuLungileyo

Iinkcukacha zeMveliso