Iimveliso

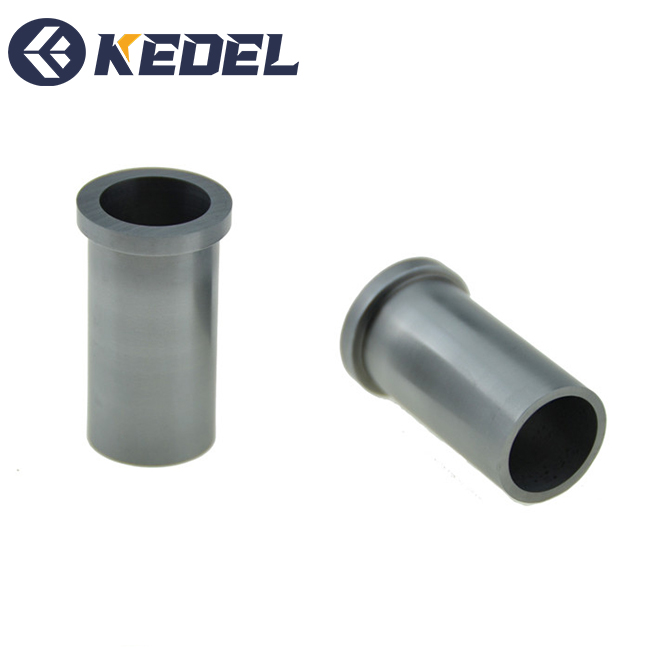

Anti Corrosion Tungsten Carbide Solid YG1C Threaded Drill Bushings

Intshayelelo yeMveliso

I-tungsten carbide bushing isekwe yi-virgin tungsten carbide material. Ibonisa ubulukhuni obuphezulu kunye namandla okugoba. Oko kunokusebenza okuphezulu ekuxhathiseni i-abrasion kunye ne-corrosion, esetyenziswa ngokubanzi kumashishini amaninzi.

Ngokusetyenziswa kwayo ngokubanzi. I-tungsten carbide bushing ihlala yenziwe ngokuchaneka okuphezulu, kwaye ngenxa yokugqitywa kwayo okugqibeleleyo, ubungakanani obuchanekileyo, ukuqina kunye nokumelana nomhlwa. Ezi zixabiswa kakhulu ngabathengi kwimarike ye-dostic kunye nangaphakathi.

Ukongeza, yahluka kwiindawo ezahlukeneyo zesicelo. Kukho iintlobo ezininzi zeTungsten carbide bushing. Uninzi lweenkcukacha zonke zenzelwe wena. Isixhobo seKedel sixhaswe lulwazi olutyebileyo lweshishini kunye namava okuvelisa ezahlukeneyo ze-tungsten carbide bushing. Oku kunokuvelisa ezahlukeneyo ze-tungsten carbide bushing esekwe kuyilo oluthile.

Iimpawu zeMveliso

1. Sebenzisa i-100% tungsten carbide imathiriyeli ekrwada

2. Iimpawu zeekhemikhali ezizinzileyo

3. Ukusebenza okugqwesileyo kunye nokunxiba kakuhle / ukuxhathisa ukubola

4. HIP sintering, compactness elungileyo

5. Izithuba, ukuchaneka okuphezulu komatshini / ukuchaneka

6. OEM ubungakanani customized ezikhoyo

7. Unikezelo lwefektri

8. Ukuhlolwa komgangatho weemveliso ezingqongqo

Umzobo weenkcukacha

Itheyibhile yezinto eziphathekayo

| IBanga | ISO | Inkcazo | Ukusetyenziswa kwe-tungsten carbide | ||

| Ukuxinana | TRS | Ukuqina | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Ufanelekile ukwenza i-iron epholileyo, i-alloy cast iron, i-refractory steel kunye ne-alloy steel. Kwakhona Ufanelekile kumatshini wentsimbi eqhelekileyo. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | Ufanelekele ukugqiba umatshini kunye nesiqingatha sokugqibela sokwenza intsimbi etyhidiweyo, isinyithi esingenawo isinyithi, i-alloy kunye nezinto ezingaxutywanga. Kwakhona ufanelekile ukuzoba umzobo wentsimbi kunye nentsimbi engeyiyo, i-drill yombane yokusetyenziswa kwe-geology kunye ne-steel drill njl. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Ufanelekele ukwenziwa kwentsimbi erhabaxa, isinyithi esingeyontsimbi, izinto ezingezizo ezentsimbi, umzobo wentsimbi, isinyithi esingenantsimbi kunye nemibhobho, izixhobo ezahlukeneyo zokusetyenziswa kwe-geology, izixhobo zokwenza umatshini kunye neenxalenye zokunxiba. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Ufanelekile kwisantya esisezantsi somatshini orhabaxa, ingxubevange yetitanium yokusila kunye nengxubevange yerefractory, ngakumbi isixhobo esisikiweyo kunye nesilika yesilika. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Ukufanelekele ukubumba izixhobo zokomba amatye anzima: amasuntswana asusekayo asetyenziselwa ukugrumba umngxuma onzulu, itroli yobhola njl.njl. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Ufanelekele ukugrumba amatye aqinileyo, imivalo yentsimbi enemilinganiselo yoxinzelelo oluphezulu, umzobo wemibhobho, izixhobo zokubhoboza, ikhabhathi engundoqo ye powder metallurgy molders ezizenzekelayo njl. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Ufanelekile ukwenza iifa ezinempembelelo ephantsi ezifana nokubetha iiwotshi zewashi, amaqokobhe ebhetri, izikrufu ezincinci njl.njl. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Ufanelekile ukwenza umngundo wesihloko esibandayo, isitampu esibandayo kunye nokucofa okubandayo okusetyenziselwa ukwenza iindawo eziqhelekileyo, iibheringi njl. | |