Ulwazi oluqhelekileyo lwensimbi engenasici

Insimbi ligama eliqhelekileyo le-iron-carbon alloys kunye nomxholo wekhabhoni phakathi kwe-0.02% kunye ne-2.11%. Ngaphezulu kwe-2.11% yintsimbi.

Ukubunjwa kweekhemikhali zetsimbi kunokwahluka kakhulu. Intsimbi equkethe ikhabhoni kuphela ibizwa ngokuba yintsimbi yekhabhoni okanye intsimbi eqhelekileyo. Kwinkqubo yokunyibilikisa isinyithi, i-chromium, i-nickel, i-manganese, i-silicon, i-titanium, i-molybdenum kunye nezinye izinto ze-alloy nazo zinokongezwa ukuphucula iimpawu zentsimbi.

Insimbi engenasici yintsimbi eneempawu eziphambili zokumelana nokugqwala kunye nokuxhatshazwa kwe-corrosion, kwaye umxholo we-chromium ubuncinci i-10.5%, kwaye umxholo wekhabhoni awukho ngaphezu kwe-1.2%.

1. Intsimbi engatyiwayo ayiyi kuhlwa?

Xa kukho amabala erusi emdaka (amabala) kumphezulu wentsimbi engatyiwayo, abantu bayamangaliswa. Bacinga ukuba isinyithi esingenasici asiyi kuhlwa. Umhlwa ayisiyontsimbi engenasici. Isenokuba ngenxa yengxaki yomgangatho wentsimbi. Enyanisweni, lo ngumbono ongalunganga wecala elinye lokungabikho kokuqonda kwensimbi engenasici. Insimbi engenasici iya kuhlwa phantsi kweemeko ezithile. Insimbi engenasici inamandla okuxhathisa i-oxidation ye-atmospheric - ukuxhathisa umhlwa, kwaye ikwazi ukuxhathisa i-corrosion kwindawo equkethe i-asidi, i-alkali kunye netyuwa, oko kukuthi, ukuxhathisa ukubola. Nangona kunjalo, ukuxhathisa kwayo kwe-corrosion kuyahluka kunye nokwakheka kweekhemikhali, imeko efanayo, iimeko zenkonzo kunye nohlobo lweendaba zokusingqongileyo. Umzekelo, i-304 imathiriyeli inokumelana ne-corrosion egqwesileyo kwimo eyomileyo necocekileyo, kodwa xa ifuduselwa kwindawo eselunxwemeni, kungekudala iya kuhlwa kwinkungu yolwandle enetyuwa eninzi. Ngoko ke, akukho naluphi na uhlobo lwensimbi engenasici enokumelana nokubola kunye nomhlwa nangaliphi na ixesha. Insimbi engenasici yifilimu ye-oxide ye-chromium enqabileyo kakhulu, eqinile kwaye ezinzileyo (ifilimu ekhuselayo) eyenziwe phezu kwayo ukukhusela ii-athomu ze-oksijini ukuba zingaqhubeki nokungena kunye ne-oxidize, ngaloo ndlela ifumana amandla okumelana nokubola. Kanye ngenxa yesizathu esithile, ifilimu isoloko yonakaliswa, i-athomu ye-oksijini emoyeni okanye ulwelo luya kuqhubeka nokungena okanye ii-athomu zentsimbi kwintsimbi ziya kuqhubeka zihlukana, zenze i-oxide yentsimbi ekhululekile, kunye nomphezulu wesinyithi uya kuhlala ugqwalile.

2. Loluphi uhlobo lwentsimbi engabizi lula ukurusa?

Kukho izinto ezintathu eziphambili ezichaphazela i-corrosion yensimbi engenasici.

I-1) Umxholo wezinto ezidibeneyo

Ngokuqhelekileyo, intsimbi ene-10.5% umxholo wechromium ayilula ukurusa. Ukuphakama komxholo we-chromium kunye ne-nickel, ngcono ukuxhathisa ukubola. Ngokomzekelo, umxholo we-nickel ye-304 yi-8% ~ 10%, kwaye umxholo we-chromium ngu-18% ~ 20%. Intsimbi enjalo engenasici ayiyi kugqwala phantsi kweemeko eziqhelekileyo.

2) Inkqubo yokunyibilikisa yamashishini emveliso

Inkqubo yokunyibilikisa yeshishini lokuvelisa iya kuchaphazela nokumelana nokugqwala kwentsimbi engenasici. Izityalo ezinkulu zensimbi ezingenasici ezinobuchwephesha obuhle bokunyibilikisa, izixhobo eziphambili kunye nobuchwepheshe obuphezulu bunokuqinisekiswa ngokumalunga nokulawulwa kwezinto ezixutywayo, ukususwa kokungcola, kunye nokulawulwa kweqondo lokushisa lokupholisa i-billet. Ngoko ke, umgangatho wemveliso uzinzile kwaye unokwethenjelwa, umgangatho wangaphakathi ulungile, kwaye akulula ukugqwala. Ngokuchasene noko, ezinye izityalo ezincinci zetsimbi zisemva kwizixhobo kunye neteknoloji. Ngethuba lenkqubo yokunyibilikisa, ukungcola akunakususwa, kwaye iimveliso eziveliswayo ngokuqinisekileyo ziya kugqwala.

3) Ubume bangaphandle

Imo engqongileyo enemozulu eyomileyo kunye nokungena komoya kakuhle akukho lula ukurusa. Nangona kunjalo, iindawo ezinomswakama ophezulu womoya, imozulu yemvula eqhubekayo, okanye i-asidi ephezulu kunye ne-alkalinity emoyeni ithanda ukuhlwa. I-304 insimbi engenasici iya kuhlwa ukuba indawo engqongileyo imbi kakhulu.

3. Indlela yokujongana namabala anomhlwa kwintsimbi engenasici?

1) Iindlela zekhemikhali

Sebenzisa intlama yokucoca iasidi okanye isitshizi ukuncedisa iindawo ezirulileyo ukuba zidlule kwakhona zenze ifilimu yechromium oxide ukubuyisela ukuxhathisa ukubola. Emva kokucoca i-asidi, ukwenzela ukususa zonke izinto ezingcolileyo kunye neentsalela ze-asidi, kubaluleke kakhulu ukuhlamba ngokufanelekileyo ngamanzi acocekileyo. Emva kwayo yonke impatho, phinda upholise ngezixhobo zokuthambisa kwaye utywine nge-wax yokupolisha. Kwiindawo ezinamabala omhlwa amancinci, i-1: 1 yepetroli kunye nomxube we-oyile ye-injini nawo unokusetyenziselwa ukosula amabala omhlwa ngamadlavu acocekileyo.

2) Indlela yomatshini

Ukucoca uqhushumbo, ukudutyulwa kweglasi okanye amasuntswana e-ceramic, ukutshabalalisa, ukuxukuxa kunye nokupolisha. Kunokwenzeka ukucima ukungcola okubangelwa izinto ezisuswe ngaphambili, izinto zokupholisa okanye izinto ezitshabalalisayo ngeendlela zoomatshini. Zonke iintlobo zongcoliseko, ingakumbi amasuntswana entsimbi angaphandle, anokuba ngumthombo wokudusa, ngakumbi kwindawo efumileyo. Ngoko ke, indawo ecociweyo ngoomatshini kufuneka icocwe ngokusesikweni phantsi kweemeko ezomileyo. Ukusetyenziswa kwendlela yomatshini kunokucoca kuphela indawo yayo kwaye ayikwazi ukutshintsha ukuxhathisa ukubola kwezinto ngokwazo. Ngoko ke, kucetyiswa ukuba uphinde uhlaziywe ngezixhobo zokupholisa emva kokucoca ngomatshini, kwaye utywine nge-wax yokupholisa.

4. Ngaba intsimbi engatyiwayo inokugwetywa yimagnethi?

Abantu abaninzi baya kuthenga insimbi engenasici okanye iimveliso zensimbi ezingenasici kwaye bazise umazibuthe omncinci kunye nabo. Xa bejonga iimpahla, bacinga ukuba intsimbi esemgangathweni ecocekileyo yeyona ingenako ukufunxa. Ngaphandle kwemagnetism, akusayi kubakho mhlwa. Enyanisweni, oku kukuqonda okungalunganga.

Ibhendi yensimbi engenamagnetic engenamagnetic igqitywe ngesakhiwo. Ngethuba lenkqubo yokuqinisa intsimbi etyhidiweyo, ngenxa yokushisa okungafaniyo kokuqina, kuya kwenza isinyithi esingenasici kunye nesakhiwo esahlukileyo njenge "ferrite", "austenite" kunye ne "martensite", phakathi kwayo "i-ferrite" kunye ne "martensite" insimbi engenasici imagnetic. "I-austenitic" yensimbi engenasici inezixhobo ezilungileyo ezibanzi zoomatshini kunye ne-weldability, kodwa "i-ferritic" yensimbi engenasici enemagnetism yomelele kune "austenitic" yensimbi engenasici kuphela ngokuxhathisa ukubola.

Okwangoku, okubizwa ngokuba yi-200 series kunye ne-300 series steels ezinomxholo ophezulu we-manganese kunye nomxholo we-nickel ophantsi kwimarike nawo awunayo i-magnetism, kodwa ukusebenza kwabo kude ne-304 enomxholo ophezulu we-nickel. Ngokuchasene noko, i-304 iya kuba nayo i-micro-magnetism emva kokwelula, ukuthambisa, ukupolisha, ukuphosa kunye nezinye iinkqubo. Ngoko ke, ukungaqondi kakuhle kunye nenzululwazi ukugweba inzuzo kunye nokungalunganga kwensimbi engenasici ngokusebenzisa insimbi engenasici ngaphandle kwemagnetism.

5. Ziziphi iimpawu zentsimbi esetyenziswa ngokuqhelekileyo?

I-201: I-Manganese isetyenziselwa endaweni ye-nickel yensimbi engenasici, ene-asidi ethile kunye nokumelana ne-alkali, ukuxinana okuphezulu, ukupolisha kwaye akukho bhubhu. Isetyenziswa kumatyala okubukela, iityhubhu zokuhombisa, iityhubhu zamashishini kunye nezinye iimveliso ezitsaliweyo ezinganzulwanga.

202: Yeye-nickel ephantsi kunye nentsimbi ephezulu ye-manganese, enomxholo we-nickel kunye ne-manganese malunga ne-8%. Ngaphantsi kweemeko ze-corrosion ezibuthathaka, ingathatha indawo ye-304, kunye nokusebenza kweendleko eziphezulu. Isetyenziswa ikakhulu kwisakhiwo sokuhombisa, uhola wendlela yokugada, ubunjineli bakamasipala, isiporo seglasi, izibonelelo zendlela, njl.

I-304: Isinyithi esingenasici esiqhelekileyo, esinokumelana nokugqwala okuhle, ukumelana nobushushu, amandla asezantsi obushushu kunye neempawu zoomatshini, kunye nokuqina okuphezulu, isetyenziswa kwishishini lokutya, ishishini lezonyango, ishishini, ishishini lemichiza kunye neshishini lokuhombisa ikhaya.

I-304L: i-carbon ephantsi ye-304 insimbi engenasici, esetyenziselwa izixhobo zezixhobo ezinokumelana nokubola kunye nokubumba.

I-316: Ngokudityaniswa kwe-Mo, inokumelana nobushushu obuphezulu be-corrosion kwaye isetyenziswa kwimimandla yezixhobo zamanzi olwandle, ikhemistri, imboni yokutya kunye nokwenza iphepha.

I-321: Inomsebenzi obalaseleyo woxinzelelo lobushushu obuphezulu kunye nokumelana nobushushu obuphezulu.

I-430: Ukudinwa okuxhathisa ubushushu, i-coefficient yokwandisa i-thermal incinci kune-austenite, kwaye isetyenziswe kwizixhobo zendlu kunye nokuhlobisa izakhiwo.

I-410: Inobunzima obuphezulu, ukuqina, ukuxhathisa okulungileyo kwe-corrosion, i-thermal conductivity enkulu, i-coefficient encinci yokwandisa, kunye nokuchasana okulungileyo kwe-oxidation. Isetyenziselwa ukwenza iatmospheric, umphunga wamanzi, amanzi kunye ne-oxidizing acid ezonakalisayo.

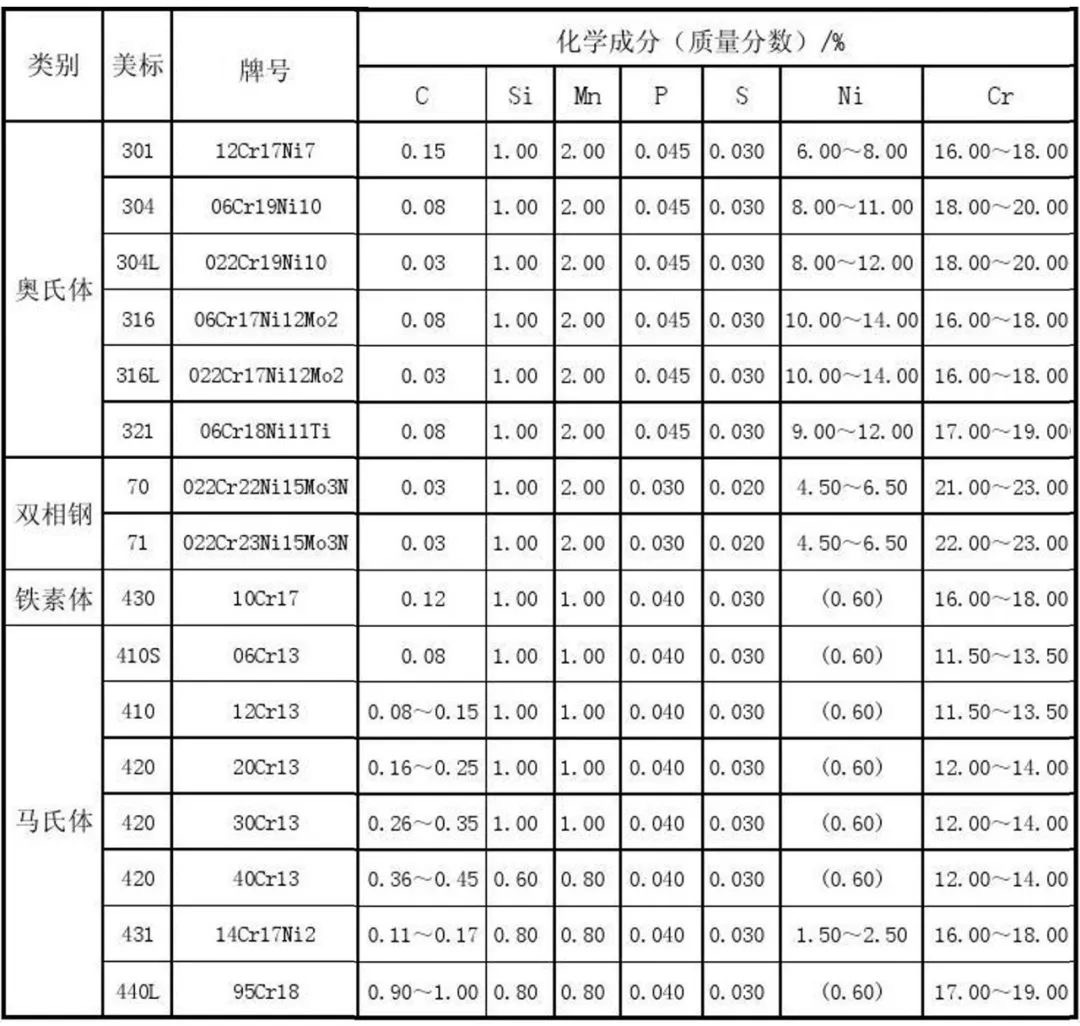

Oku kulandelayo yitheyibhile yomxholo "yezinto ze-alloy" zamabakala ahlukeneyo ensimbi yentsimbi eqhelekileyo yokubhekisela kuphela:

Ixesha lokuposa: Jan-30-2023