Iimveliso

Iseti ye-Rotary Carbide Burrs

KEDEL ISIXHOBO se-carbide burr isethi yodidi

Sibonelela ngeendidi ezi-3 zeeseti ze-1/4″ okanye i-6mm shank carbide burrs, equlathe 5, 8, okanye 10 burrs ngokulandelelanayo. Ukulungiswa kombala wetyala kuyafumaneka. Ungasebenzisa ukhetho lwethu olucetyiswayo lwe-burr bits okanye uzakhele ngokwakho.

Sibonelela ngeendidi ezi-2 zeeseti ze-1/8”(3mm) ii-shank rotary burrs, eziqulathe ii-burrs ezingama-20 okanye ezingama-40 ngokulandelelanayo.Ungasebenzisa iibhithi ezicetyiswayo ezikhethiweyo okanye uzakhele ngokwakho.

Inzuzo Yethu

Yenziwe nge-100% ye-WC enyulu engumgubo

Sebenzisa kuphela imathiriyeli ekrwada ekumgangatho ophezulu (zombini iTungsten carbide powder&shank yentsimbi)

Itekhnoloji ye-welding ye-CNC ibangela ukuba i-burr bit ayizange isuswe kwi-shank kwimbali

Yenziwe yimigca yemveliso ye-CNC epheleleyo evela kwi-welding, ukugawula, ukupolisha, kunye nokucoca kuqinisekisa zombini umgangatho ongaguqukiyo kunye nokusebenza kakuhle kwemveliso.

Isampulu yasimahla Iyafumaneka

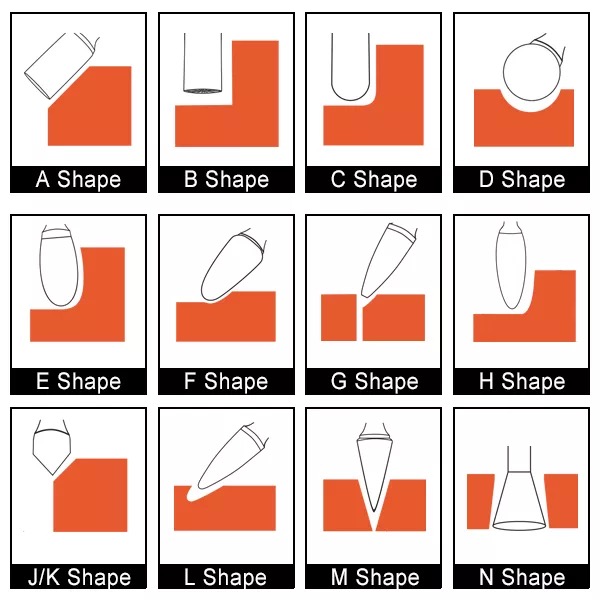

Imilo ekhoyo

Ubume A Cylindrical Plan End

Ubume B Cylindrical End Cut

Imilo C Cylindrical Ball Nose

Imilo yeBhola ye-D

Imilo E Oval Shape

Imilo F Umthi Radius End

Imilo yeMilo ye-G yoMthi

Shape H Flame Shape

Ubume J 60-degree countersink

Ubume K 90 degree countersink

Imilo L Cone Radius End

Imilo yekowuni enguM eJombe imilo

Imilo N Ikhowuni eguqulweyo