Iimveliso

Iintonga zeTungsten eziqinileyo zeCarbide

Carbide Rods Inkcazo

Iintsimbi ze-tungsten ze-carbide zisetyenziselwa ngokubanzi ukudala izixhobo ze-carbide eziqinileyo ze-premium, ezifana ne-mill end, i-drills, i-reamers, i-milling cutters, i-stamping, kunye nezixhobo zokulinganisa kumashishini ahlukeneyo. Ukukhetha okusemgangathweni okubanzi kweentonga ze-tungsten carbide kwimilinganiselo eyahlukeneyo kuyafumaneka, kwaye sinikezela ngeenkonzo zokwenza ngokwezifiso ngokweemfuno zakho. Njengomvelisi we-ISO, i-Kedeltool isebenzisa izinto ezisemgangathweni ophezulu ukuqinisekisa umgangatho kunye nokusebenza kweentonga zethu ze-carbide. Ngokuhlolwa komgangatho ongqongqo, sinokuqinisekisa umgangatho ongaguqukiyo kwibhetshi nganye.

Iintlobo zeentonga zeKedel Carbide

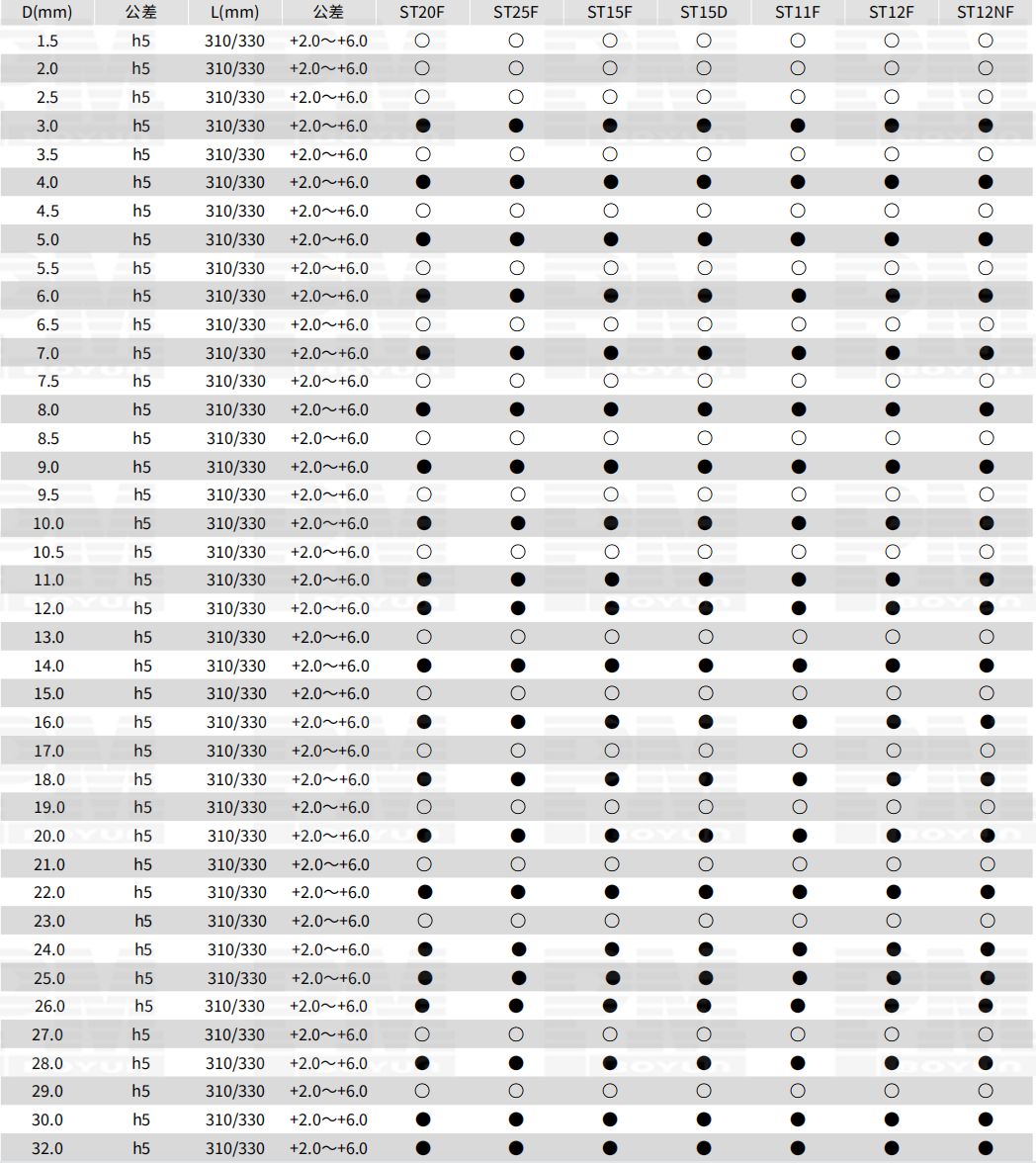

1. Iintonga zeCarbide eziqinileyo kwiiMetrikhi

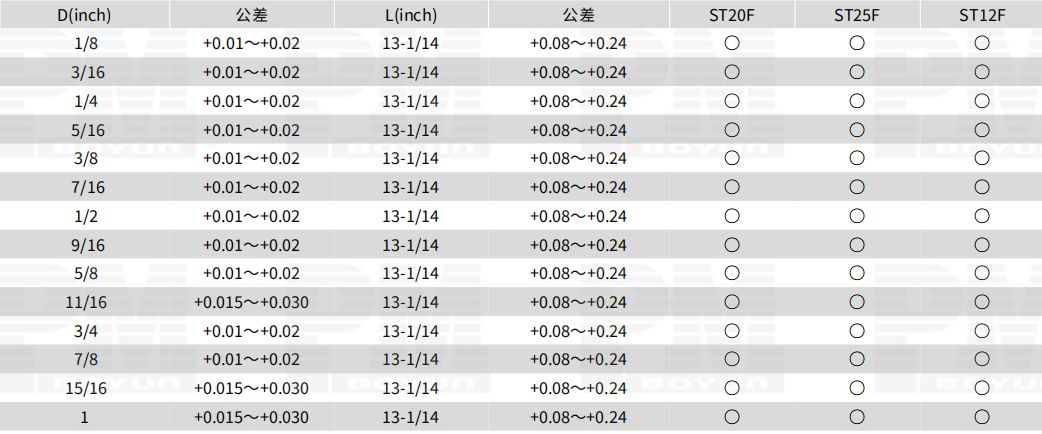

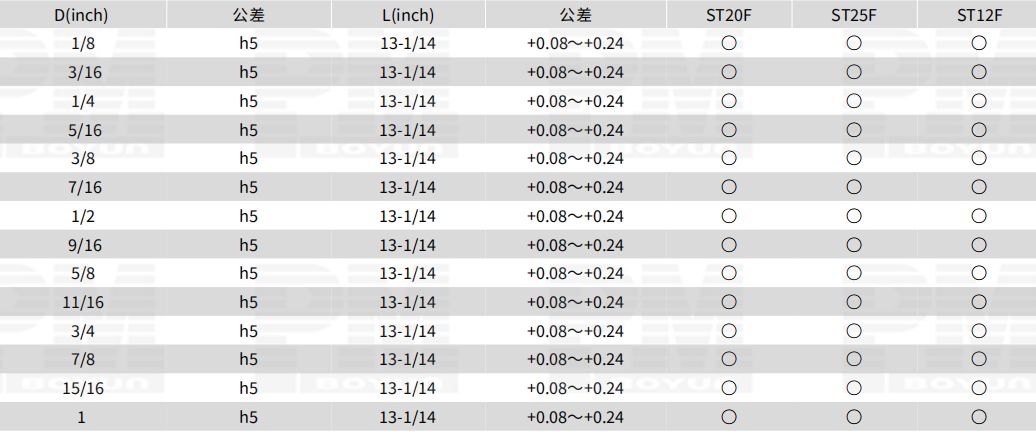

2. Iintonga zeCarbide eziqinileyo kwii-intshi

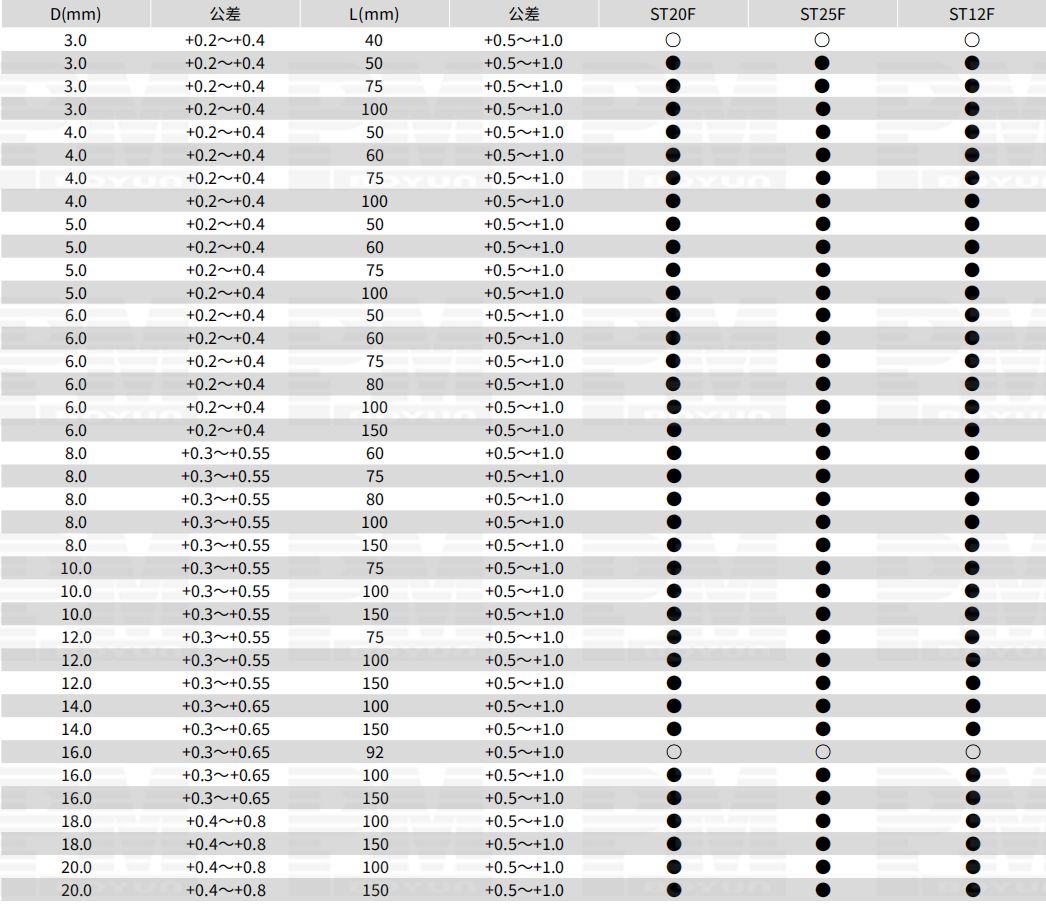

3. I-Drill Blanks (I-Chamfered)

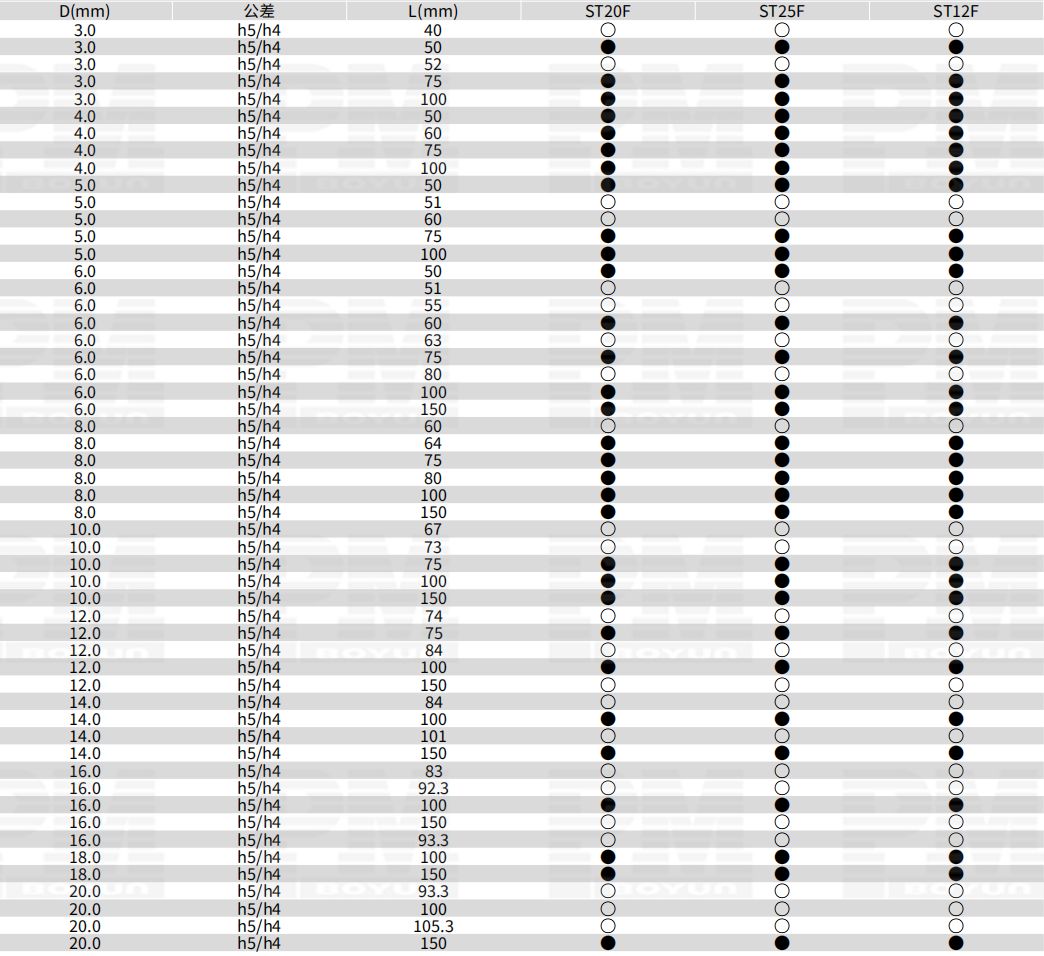

4. End Mill Blanks (Chamfered)

5. Iintonga zeCarbide ezinoMngxuma wokuPholisa oNgqongileyo oseMbindini

6. Iintonga zeCarbide ezinemingxuma emibini yokuPholisa eNgqo

Iimpawu zeCarbide Rod

1. Yenziwe ngomgangatho ophezulu we-tungsten carbide superfine powder

2. Izixhobo ezichanekileyo kunye ne-10MPa ye-HIP-Sinter yesitovu eyenziwe ngokusemgangathweni.

3. Ubunzima obuphezulu kunye namandla aphezulu

4. Iingenelo ezikhethekileyo: Ubunzima obubomvu, ukunyamezela ukunxiba, imodyuli ephezulu, i-TRS, ukuzinza kweekhemikhali, ukuxhathisa impembelelo, i-coefficient ephantsi ye-dilatation, i-heat conduction kunye ne-electric conduction efanayo nentsimbi.

5. I-teknoloji ekhethekileyo: i-high pressure sintering ye-vacuum ephezulu yokushisa. Ukunciphisa i-porosity, ukunciphisa ukubumbana kunye nepropati yomatshini. Imigangatho eyahlukeneyo, iintlobo kunye nobukhulu.

6. Ibakala elahlukileyo kwireferensi yakho.

Ubungakanani obuqhelekileyo

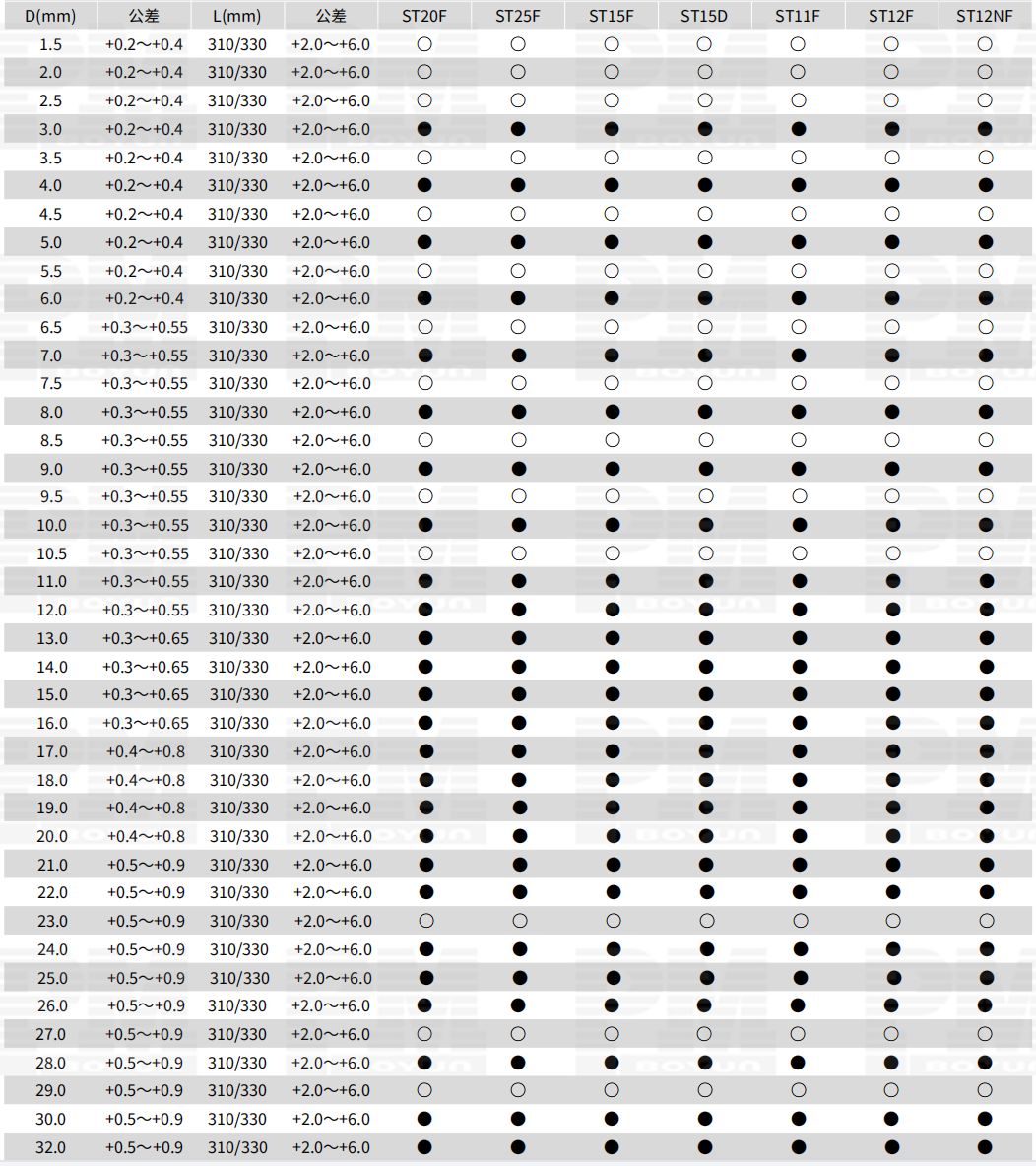

Uluhlu lweBanga

| Intshayelelo yeBanga kwiCarbide Rods | |||||||

| IBanga | Co % | Ubungakanani beenkozo zeWC | HRA | HV | Ubuninzi (g/cm³) | Amandla okugoba (MPa) | Ukuqina kokwaphuka (MNm-3/2) |

| I-KT10F | 6 | I-submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| I-KT10UF | 6 | kakuhle kakhulu | 93.8 | 2040 | 14.7 | 3200 | 9 |

| I-KT10NF | 6 | inanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| I-KT10C | 7 | Kulungile | 90.7 | 1480 | 14.7 | 3800 | 12 |

| I-KT11F | 8 | I-submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| I-KT11UF | 8 | kakuhle kakhulu | 93.5 | 1960 | 14.5 | 3000 | 9 |

| I-KT12F | 9 | kakuhle kakhulu | 93.5 | 1960 | 14.4 | 4500 | 10 |

| I-KT12NF | 9 | inanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| I-KT15D | 9 | I-submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| I-KT15F | 10 | I-submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| I-KT20F | 10 | I-submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| I-KT20D | 10 | I-submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| I-KT25F | 12 | kakuhle kakhulu | 92.4 | 1740 | 14.1 | 5100 | 10 |

| I-KT25EF | 12 | kakuhle kakhulu | 92.2 | 1700 | 14.1 | 4800 | 10 |

| I-KT25D | 12 | kakuhle kakhulu | 91.5 | 1570 | 14.2 | 4200 | 13 |

| I-KT37NF | 15 | inanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Ngolwazi olongezelelweyo (MOQ, ixabiso, ukuhanjiswa) okanye ukuba ufuna iinkonzo zokwenza ngokwezifiso, nceda ucele ikowuti.